PKP-1100-LI

First introduction to the PKP Series Keypad?

Here is a short product overview video.

SOFTWARE FEATURES

Assign any valid CAN address to the keypad. Communicate on either BUS simultaneously.

The button no longer has to be pre-programmed to a specific address. This enables customers that work in applications in the field without access to a GUI to use any

replacement device on-hand. The button can be configured to automatically announce itself and accept a new address assignment as appropriate.

The button can send messages to the bus indicating a press/release event has occurred. This confirmation allows digital systems to have the same input acknowledgements as that of the latching position of a mechanical switch.

The button sends a continuous broadcast of messages indicating the press or release status. The frequency of these messages can be adjusted in a wide range.

An online set-up system makes it possible to select and design your own prototype, then order it directly on blinkmarine.com.

The button sends a continuous broadcast of messages indicating the press or release status. The frequency of these messages can be adjusted in a wide range.

Fully compliant with Device Profile 401d.

HARDWARE FEATURES

SPECIFICATIONS FOR STANDARD KEYPADS

ELECTRICAL

| Supply Voltage | 12-24Vdc Nominal (8-32VDC) |

| Standby Current | <50 mA |

| Communication BUS | CANopen, J1939 |

| Hardwired button current | 100mA Max |

| Hardwired button voltage | 35V Max |

| MTBF | 210899 hours (in accordance with MIL-HDBK-217 – operating environment ground mobile) |

MECHANICAL

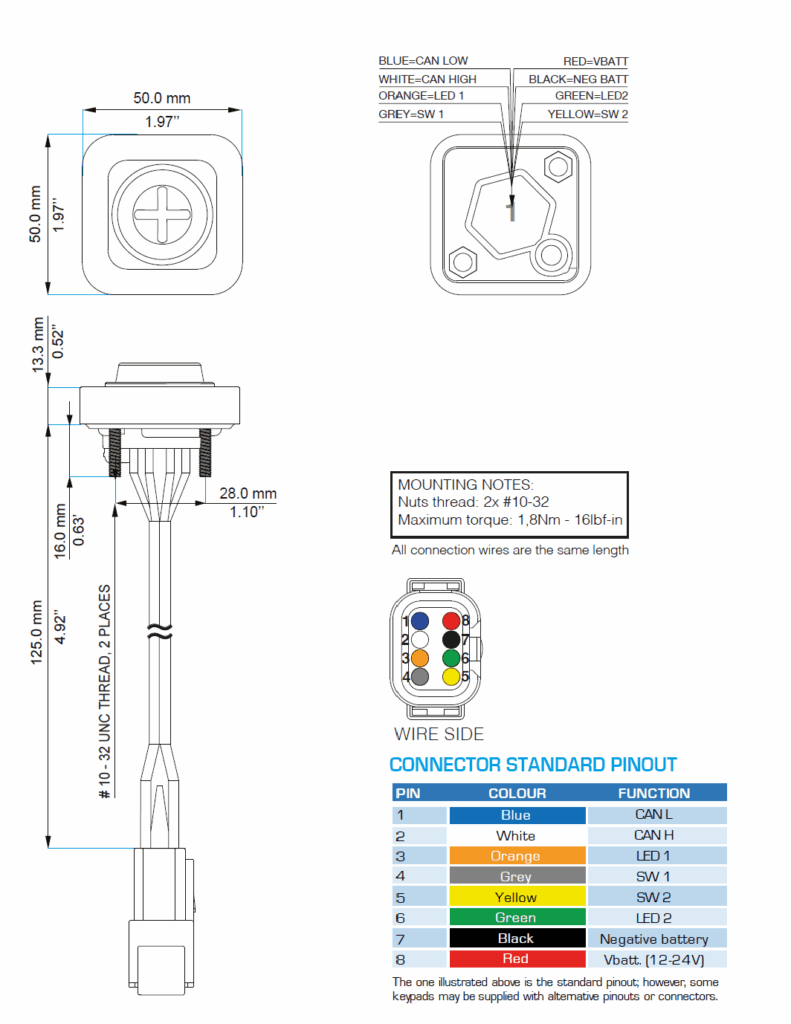

| Standard Connector | Deutsch DTM04-8P |

| Switch Life | 1 million operations |

| Mounting Studs | 2x #10-32 Steel |

| Keypad | Silicone rubber with polyurethane hardcoat |

| PC Board | 1,6mm thick, Nema Grade FR-4, double clad with 1oz copper |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Thermal Shock | -40°C to +85°C According to table 2 of ISO16750-4 |

| Vibration Test | IEC 60068 2-6 3-axis X,Y,Z 10-150Hz 0.15mm |

| UV Protection | UVB 400 hours |

| Salt Spray | Per ASTMB117 |

| Chemical Resistance | Engine Cleaner, Isopropyl Alcohol, Suntan Lotion, Multi-Purpose Cleaner, Muriatic Acid |

| Ingress protection Rating | IP67/IP69K |

| Weight | 90 gr (Inserts excluded) |