PKP-3500-SI-MT

PKP-3500-SI-MT The PKP-3500-SI-MT represents a significant step forward in CANbus keypad technology, equipped with a refined design that includes thirteen push buttons with customizable icon inserts and two push-activated rotary encoders. This keypad also features four additional analog and digital inputs, facilitating the direct connection of 5V sensors to the CANbus network. Its compact design and inclusion of rotary encoders save considerable dash space and expand vehicle functionality. The IP67-rated PKP-3500-SI-MT2 version provides increased detent torque for superior haptic feedback.

SHOP NOWSOFTWARE FEATURES

Assign any valid CAN address to the keypad.

Keypads no longer have to be pre-programmed to a specific address. This enables customers that work in applications in the field without access to a GUI to use any replacement keypad on-hand. The keypad can be configured to automatically announce its address and accept a new address assignment as appropriate.

The keypad can send messages to the BUS indicating a button press or a button release event has occurred. This confirmation allows digital systems to have the same input acknowledgements as that of the latching position of a mechanical switch.

The keypad sends a continuous broadcast of messages indicating the press or release status of each button at that instance. The frequency of these messages can be adjusted in a wide range.

The keypad sends a continuous broadcast of messages indicating it is functioning correctly. The frequency of these messages can be adjusted in a wide range.

Fully compliant with Device Profile 401d.

HARDWARE FEATURES

SPECIFICATIONS FOR STANDARD KEYPADS

ELECTRICAL

| Supply Voltage | 12-24Vdc Nominal (8-32VDC) |

| Standby Current | <50 mA |

| Communication BUS | CANopen, J1939 |

MECHANICAL

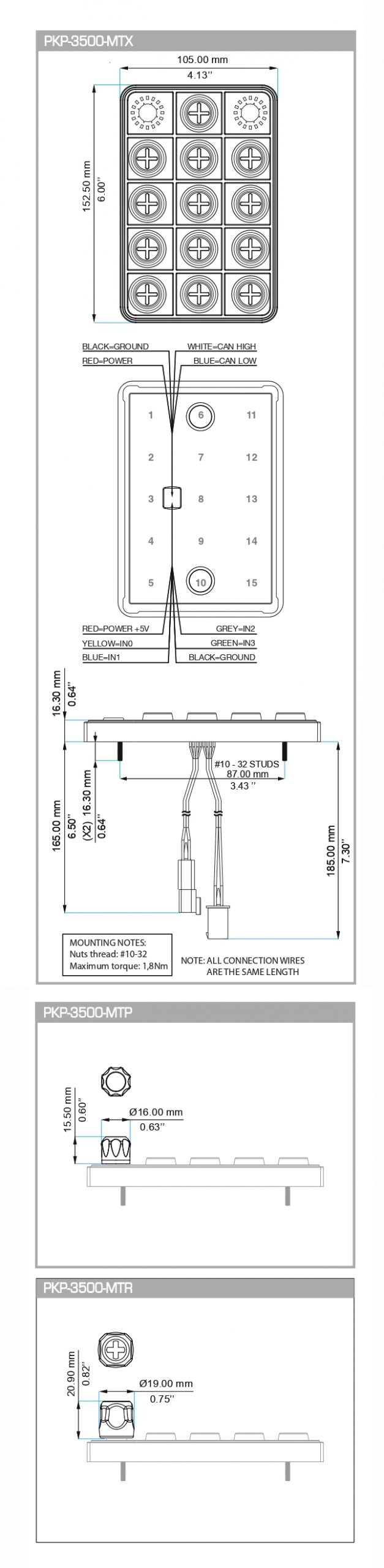

| Connector | Deutsch DT04-4P + Molex 39-01-3069 |

| Switch Life | 3 million operations |

| Mounting Studs | #10-32 Steel |

| Keypad | Silicone rubber with polyurethane hardcoat |

| PC Board | 1,6mm thick, Nema Grade FR-4, double clad with 1oz copper |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Thermal Shock | -40°C to +85°C According to table 2 of ISO16750-4 |

| Humidity | 0 to 98% (no condensation) |

| UV Protection | UVB 400 hours |

| Salt Spray | Per ASTMB117 |

| Chemical Resistance | Deet, Engine Cleaner, Isopropyl Alcohol, Suntan Lotion, Multi-Purpose Cleaner, Orange Citrus Cleaner, Muriatic Acid |

| Weight | 300 gr (Inserts excluded) |